Page 49 - 2026 HuFriedyGroup Digital Catalog

P. 49

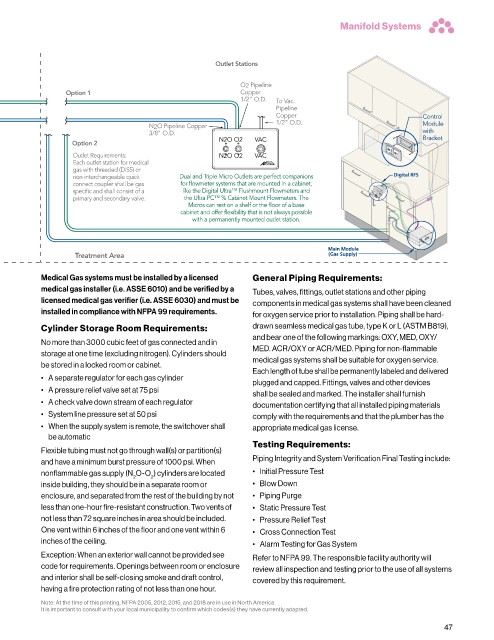

Mains and branches in piping systems shall be not less Outlet Stations

than 1/2'' nominal size.

O2 Pipeline

6 1/2'' MEDICAL GAS CONTROL VALVES Option 1 Copper

CLOSE IN EMERGENCY ONLY ZONE VALVE

FOR USE WITH 1/2" O.D. To Vac.

Automatic Manifold System

Oxygen

O 2 (PSI)

Nitrous Pipeline

Oxide

(PSI)

ZONE VALVE #

PULL RING FOR ACCESS Copper Control

N 2 O 1/2" O.D. Module

N2O Pipeline Copper

Wall Mount Cat 6 cable to 3/8" O.D. with

Bracket

Office Alarm Panel Zone Valve (100') Zone Valve Option 2 N2O O2 VAC

Outlet Requirements: N2O O2 VAC

Each outlet station for medical

gas with threaded (DISS) or

non-interchangeable quick Dual and Triple Micro Outlets are perfect companions

Copper to copper joints shall be braised using connect coupler shall be gas for flowmeter systems that are mounted in a cabinet,

copper-phosphorus or copper phosphorus-silver

Cat 6 cable brazing filler metal (B cup series) without flux with specific and shall consist of a like the Digital Ultra™ Flushmount Flowmeters and

to Office at least 1000˚ F. melting point. While being primary and secondary valve. the Ultra PC™ % Cabinet Mount Flowmeters. The

Alarm Panel brazed, joints shall be continually purged with Micros can rest on a shelf or the floor of a base

(100') oil-free dry nitrogen. The flow of purge gas shall cabinet and offer flexibility that is not always possible

be maintained until the joint is cool to touch. with a permanently mounted outlet station.

Dental Office Area Treatment Area

Cylinder Storage Area (Central System Manifold Room)

Medical Gas systems must be installed by a licensed General Piping Requirements:

medical gas installer (i.e. ASSE 6010) and be verified by a Tubes, valves, fittings, outlet stations and other piping

Cat 6 to licensed medical gas verifier (i.e. ASSE 6030) and must be components in medical gas systems shall have been cleaned

Alarm Panel installed in compliance with NFPA 99 requirements. for oxygen service prior to installation . Piping shall be hard-

Cat 6 to 110 volt Cylinder Storage Room Requirements: drawn seamless medical gas tube, type K or L (ASTM B819),

Zone Valve outlet within 6’ and bear one of the following markings: OXY, MED, OXY/

No more than 3000 cubic feet of gas connected and in MED . ACR/OXY or ACR/MED . Piping for non-flammable

Optional Source Valves storage at one time (excluding nitrogen) . Cylinders should medical gas systems shall be suitable for oxygen service .

be stored in a locked room or cabinet . Each length of tube shall be permanently labeled and delivered

• A separate regulator for each gas cylinder plugged and capped . Fittings, valves and other devices

• A pressure relief valve set at 75 psi shall be sealed and marked . The installer shall furnish

• A check valve down stream of each regulator documentation certifying that all installed piping materials

• System line pressure set at 50 psi comply with the requirements and that the plumber has the

Pressure Relief Valve (N2O) Pressure Relief Valve (O2) appropriate medical gas license .

N2O DISS Hose O2 DISS Hose (3 feet) • When the supply system is remote, the switchover shall

(3 feet) O2 Regulator be automatic Testing Requirements:

Flexible tubing must not go through wall(s) or partition(s) Piping Integrity and System Verification Final Testing include:

N2O Regulator 5’ (60”) AFF and have a minimum burst pressure of 1000 psi . When • Initial Pressure Test

(Above nonflammable gas supply (N O-O ) cylinders are located

Finished 2 2 • Blow Down

Nitrous Nitrous Floor) Oxygen Oxygen inside building, they should be in a separate room or

Oxide Oxide • Piping Purge

enclosure, and separated from the rest of the building by not

less than one-hour fire-resistant construction . Two vents of • Static Pressure Test

Cylinder Restraints

not less than 72 square inches in area should be included . • Pressure Relief Test

One vent within 6 inches of the floor and one vent within 6 • Cross Connection Test

inches of the ceiling . • Alarm Testing for Gas System

Exception: When an exterior wall cannot be provided see Refer to NFPA 99 . The responsible facility authority will

code for requirements . Openings between room or enclosure review all inspection and testing prior to the use of all systems

Nitrous Oxide Supply Oxygen Supply and interior shall be self-closing smoke and draft control, covered by this requirement .

having a fire protection rating of not less than one hour .

For Category 1 projects, we’ve partnered with

Note: At the time of this printing, NFPA 2012, 2015, 2018, 2021 and 2024 are in Ohio Medical to deliver solutions to dental offices.

use in North America . It is important to consult with your local municipality to

confirm which codes(s) they have currently adapted . Ask your PSA rep for more details.

47